24-hour service hotline:0755-29103270

Welcome to Shenzhen Zhongjing Global Purification Technology Co., Ltd.!

backtrackCurrent location:Home / Engineering / Pharmaceutical GMP purification workshop

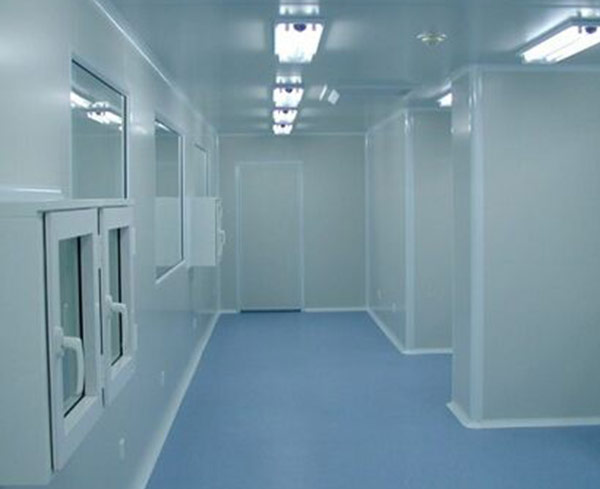

Zhongjing Global is committed to the design and construction...

The clean room (area) is an indispensable production environ...

Zhongjing Global is committed to the design and construction...

The basic requirements for the workshop design of the Chinese Herbal Pieces Factory are: according to the variety and quantity of the production pieces, the design workshop and its size. For example, the crushing workshop (room) requires a ...

MORE >>

The raw material purification workshop room parameters will affect the product and materials, including temperature, humidity and suspended particles, and microorganisms are also an important indicator for certain pharmaceutical intermediat...

MORE >>

GMP stipulates that for the raw materials produced by the fermentation process, since the raw materials used may create conditions for microbial contamination, special attention should be paid to prevent microbial contamination during the p...

MORE >>

Fire pipes are installed in the air ducts through the engine room, floor slabs and fire compartments; all fire dampers and fans are linked to the fire alarm system.

MORE >>

the pharmaceutical packaging materials include: medicinal butyl rubber stopper, PTP aluminum foil for pharmaceutical packaging, medicinal PVC hard sheet, medicinal plastic composite hard sheet, composite film (bag), plastic infusion bottle ...

MORE >>

Summary The blood product production workshop should include the following production areas: plasma storage area, melt-breaking bag-breaking area (including separation of cryoprecipitate and PCC adsorption separation), separation of crude f...

MORE >>

Genetic engineering: including genetic testing, recombination, sequencing

MORE >>

Commonly used solid dosage forms include powders, granules, tablets, capsules, pills, films, etc.

MORE >>

The number of air changes in the clean workshop is based on the requirements set out in the \"Good Manufacturing Practices\". The design uses a 100,000-level clean area: the number of air changes is 10 to 20 times / hour; the level of clean...

MORE >>

\"Code for Design of Clean Plants\" GB50 73-20 1 1. Cleanliness level of suspended particles in air, concentration of suspended particles

MORE >>

GMP projects include: solid preparations, large infusions, blood products, veterinary drugs GMP, health foods, etc.

MORE >>